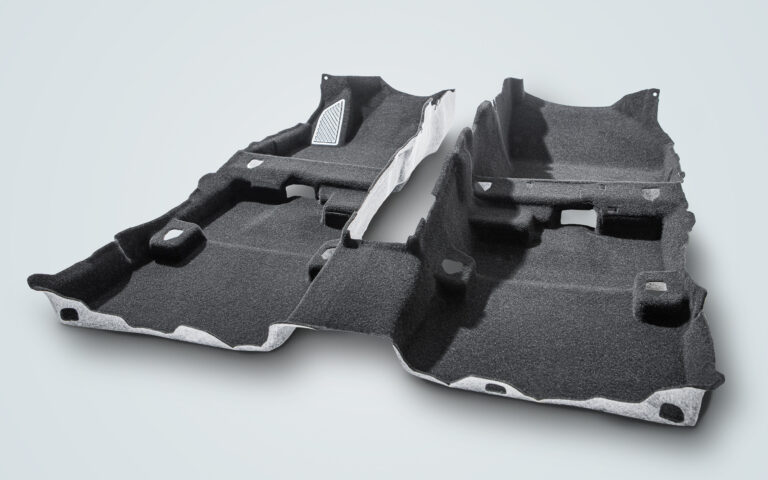

Autoneum has developed the N-Join1, a monomaterial carpet system made from recycled materials that eliminates the need for latex and adhesives, offering an eco-friendly solution for vehicle interiors.

The N-Join1 employs a process that joins the carpet surface together with the substrate in a single step. The substrate can be made from various materials, including Autoneum’s Pure technology components made of 100% polyester, making N-Join1 easier to recycle.

N-Join1 is designed to support driving comfort by contributing to noise protection in the passenger cabin and can be used together with the Di-Light carpet, which offers an attractive, uniform surface finish.

The monomaterial construction enables waste-free production and full recycling at the vehicle’s end-of-life. By eliminating the use of latex, which is water and energy-intensive, N-Join1 also reduces resource use and ensures cleaner production. Autoneum says that the carpet system has a reduced carbon footprint compared to traditional carpet systems of equal weight.

N-Join1 is suitable for a wide range of vehicles, including both internal combustion engine (ICE) vehicles and battery electric vehicles (BEVs).

In related news, SK Chemicals has signed a partnership agreement with Austrian automotive carpet manufacturer Durmont and Paarang to supply recycled materials to global automotive brands. Read the full story here