EconCore, a provider of lightweight thermoplastic honeycomb core technology, has signed a licensing agreement with a Japanese automotive Tier 1 supplier.

The Leuven, Belgium-based company signed the deal with Kotobukiya Fronte, which already uses the honeycomb technology for automotive interiors.

The Japanese firm is developing lightweight solutions for automotive interiors.

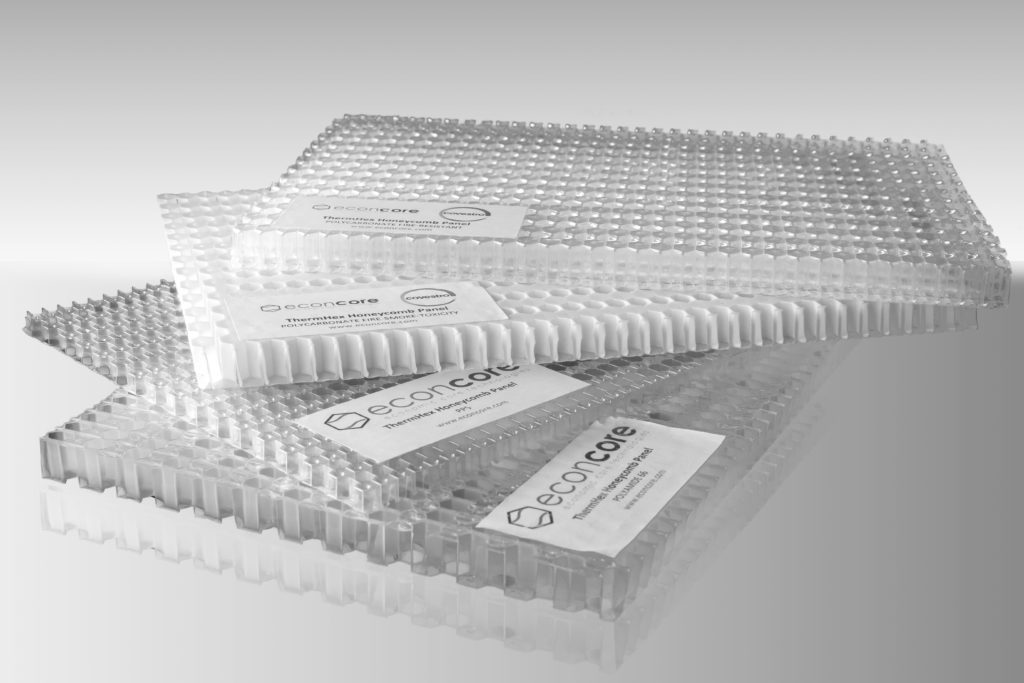

EconCore says producing rigid panels integrated with in-line lamination of non-woven and carpet surface layers enables a more efficient production process of finished automotive interiors.

They feature enhanced acoustic performance due to the cellular thermoplastic honeycomb structure.

The lightweight honeycomb panels can be converted into relatively complex-shaped parts with a short compression molding process cycle.

Dr Jochen Pflug, CEO of EconCore, said, “The technology opens the way for product developments that are cost-effective, strong, and at the same time lightweight, and can be made on a continuous production line.”