Toyoda Gosei has developed a new technology to recycle high-quality plastic from end-of-life vehicles (ELV) in order to meet the growing demand for recycled plastic in the automotive industry against a backdrop of strengthened environmental regulations. This technology is designed to contribute to a decarbonized, circular economy, and will be implemented in various vehicle models, starting with the Toyota Camry.

It is often difficult to obtain recycled plastic with performance equivalent to that of new material due to impurities or other factors, and so waste plastic has generally been burned to recover heat (thermal recycling) or reused for purposes with lower required performance (downcycling).

However, Toyoda Gosei has developed a recycled plastic with performance equivalent to that of new material, even with 50% ELV plastic (polypropylene). To achieve this, the company has collaborated with Isono Co. to procure quality raw materials for recycling and leveraged its original material modification technology, meeting the quality standards for automotive parts for practical application. This technology accelerates horizontal recycling for reuse in the same parts and contributes to CO2 reduction, Toyoda Gosei says.

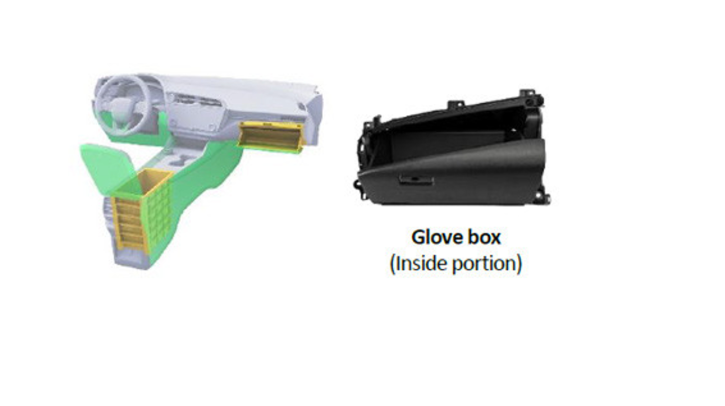

The company says it is the first time that recycled plastic containing 50% ELV plastic has been used in interior parts such as glove boxes that require impact resistance.

Going forward, Toyoda Gosei aims to expand the range of applicable products, such as those associated with vehicle design, and will continue to improve the attributes of recycled plastic.

In related news, TechnoCompound and RE Plano, a subsidiary of Remondis Recycling, recently announced that they are expanding their collaboration on the use of post-consumer recyclates in automotive products. Click here to read the full story