The forthcoming 2026 BMW iX3 50 xDrive has been developed with a focus on reducing the product’s environmental footprint that, the auto maker says, demonstrates the group’s “take on implementing a holistic approach to product sustainability across the entire lifecycle”.

During product development, measures were implemented throughout the supply chain, production and use phases that prioritize decarbonization and resource conservation, BMW says.

CO₂e benefits after one year of use

Electric vehicles can start with a higher carbon footprint, primarily from battery production, but because they produce no tailpipe emissions and are powered by electricity — which is becoming increasingly cleaner — their overall emissions per kilometer decrease over time. When compared with internal combustion engine (ICE) vehicles, which continue to produce emissions throughout their lifetime, an EV’s sustainability can be quantified by calculating the distance the vehicle travels until it breaks even.

The decarbonization measures put in place by BWM in the supply chain during the development of the iX3 have resulted in an early break-even point for the Neue Klasse vehicle.

Based on the Worldwide Harmonised Light Vehicle Test Procedure (WLTP), when the BMW iX3 50 xDrive is charged with electricity from the average European energy mix, its CO₂e footprint is lower than those of a comparable internal combustion engine (ICE) model after approximately 21,500km of driving. When the iX3 is charged exclusively with electricity from renewable sources, it beats the comparable ICE model after around 17,500km.

Design for circularity: Interior

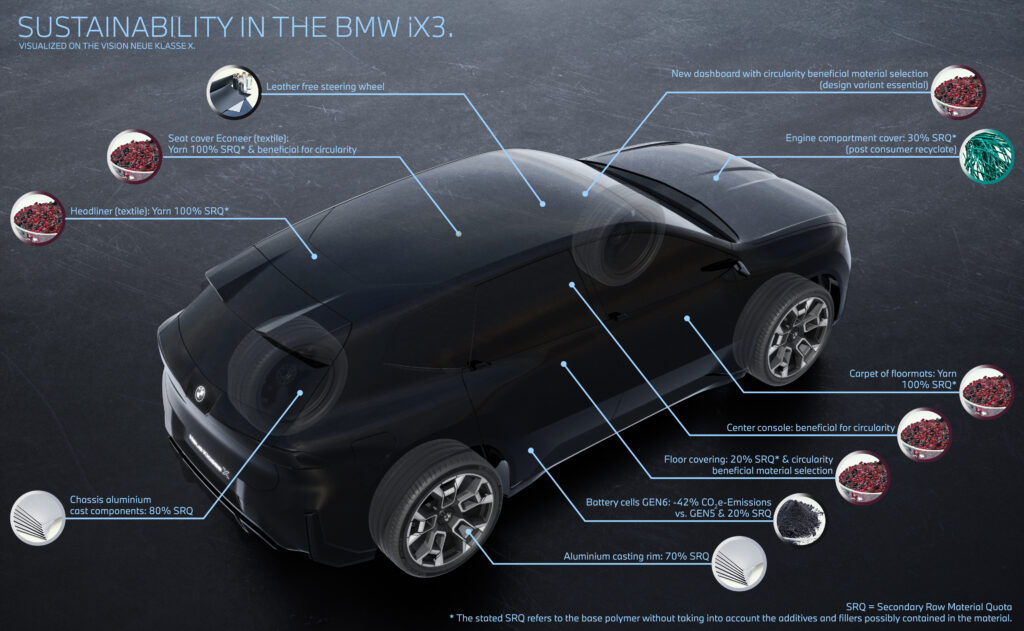

The BMW Group prioritized the use of secondary materials, strategic material selection and disassembly optimization to reduce CO₂e emissions. As a result, secondary materials account for one third of all materials used in the iX3 50 xDrive.

One example of the implementation of these three concepts is the Econeer seat cover, available in the interior trim Essential, for which the fabric, adhesive and fleece are all made from PET. This mono-material choice increases recyclability and the textile yarn used consists entirely of recycled PET as well. Other components that prioritize the circularity approach include the center console, instrument panel and interior floor trim (below).

Decarbonization in the supply chain

BMW achieved a 35% reduction in CO₂e emissions in the supply chain during product development through the use of secondary materials and renewable energy and the implementation of innovations in both products and processes.

The Gen6 battery cells of the BMW iX3 high-voltage storage system are made of 50% secondary cobalt, lithium and nickel materials and renewable energies have been harnessed in the anode and cathode materials and cell production. This has resulted in a 42% reduction of CO₂e emissions per watt-hour compared to the Gen5 cell of the previous model.

BMW has also used innovative and secondary materials in other components. For example, 30% of the secondary raw material used for the engine compartment cover and the storage compartment under the front hatch is recycled maritime plastic – this post-consumer material consists of old fishing nets and ropes – and secondary aluminum accounts for 80% of the wheel carriers and swivel bearings as well as 70% of the cast aluminum wheels.

Use phase efficiency

BMW’s ‘EfficientDynamics’ approach – which “systematically optimizes every aspect of the vehicle”, according to the auto maker – was employed to maximize efficiency across all vehicle systems. As a result, the new BMW iX3 consumes 20% less energy than its predecessor (WLTP combined) through improved aerodynamics, reduced rolling resistance and lower onboard power consumption, and what BMW terms “the drive’s unparalleled combination of efficiency and dynamics”.

In related news, the Fraunhofer Institute for Process Engineering and Packaging IVV in Germany has further developed its technology to selectively dissolve target polymers from waste streams and potentially remove critical legacy additives, in order to meet the high requirements for processability and odor emissions for reuse in vehicle interiors. Read the full story here