UK-based automotive parts manufacturer Techniplas has launched a new injection molding and painting process for direct fabrication and surface coloring – called ColorFuse.

Material cost savings with ColorFuse can be as high as 35% compared with standard wet painting processes while still achieving the same high gloss piano black appearance in an A-Pillar application and fulfilling the scratch-resistance criteria.

ColorFuse can be integrated into existing manufacturing processes without investment in complex painting lines. Compared with conventional processes, colors can be changed much faster as the paint coating is applied directly to the part in the closed mold, removing an entire step from the production process to decrease production times.

Independent of the carrier material, a molded part is flow-coated with a polyurea reactive lacquer while still in the multi-component tool and then leaves the mold in the desired color with no extension to the injection molding cycle.

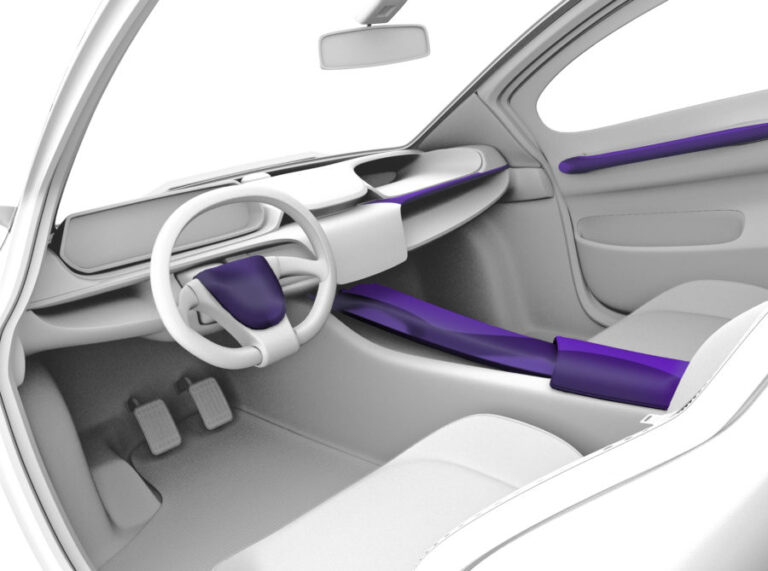

“ColorFuse changes the game for coloring interior and exterior car parts,” said Daniel Spirig, president of Techniplas Prime and ColorFuse. “Manufacturers gain a one-step process of injection molding and painting combined for direct surface coating with no post mold processing. By combining these processes, parts can be manufactured faster at lower cost with innovative design options including elegant surface aesthetics and logo depictions.”

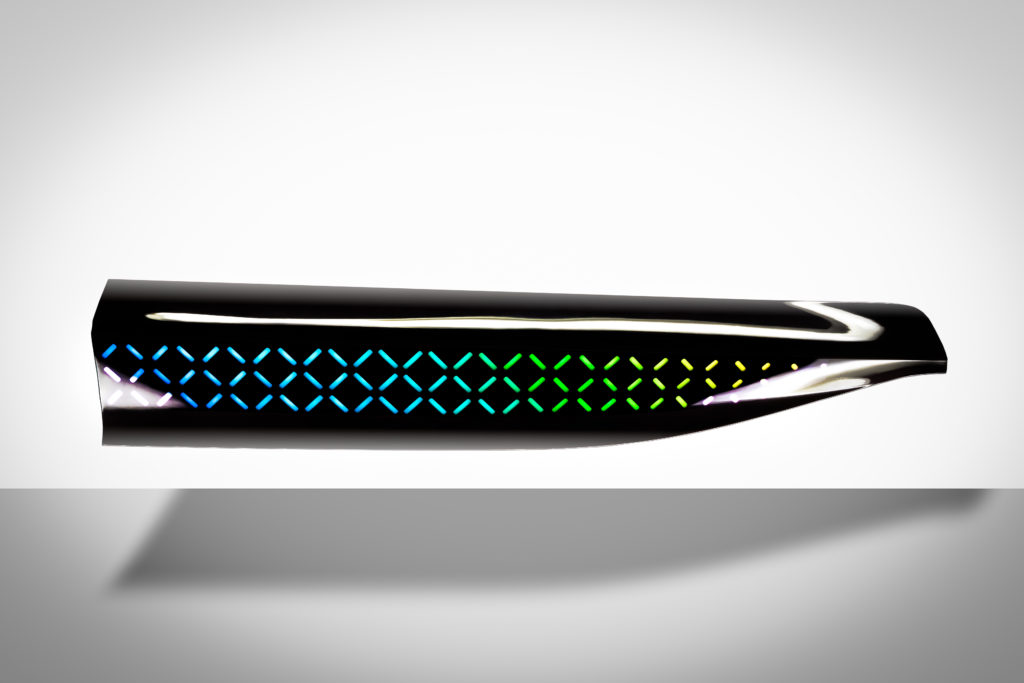

Unlike genuine metal surfaces, ColorFuse metal effect surfaces are largely scratch resistant and resilient against climatic and environmental effects such as UV radiation. Manufacturers can choose from a variety of colors, varying surface textures, clear coat surfaces with depth effects, partial textures, designer lines and lettering.

Enabling precise accents and styling lines, ColorFuse offers high gloss, matte or grained surfaces for car interiors and exteriors.

“ColorFuse not only provides best in class surfaces at very competitive prices; we also combine it with our wider Techniplas technologies and offerings to deliver a complete range of production capabilities,” added Spirig.